Like Mike, I prefer to paint the basic structure after it's been assembled. This allows you to make alterations and touch-up areas where the parts don't fit as well as they should - this is especially true of corners, particularly on structures representing masonry.

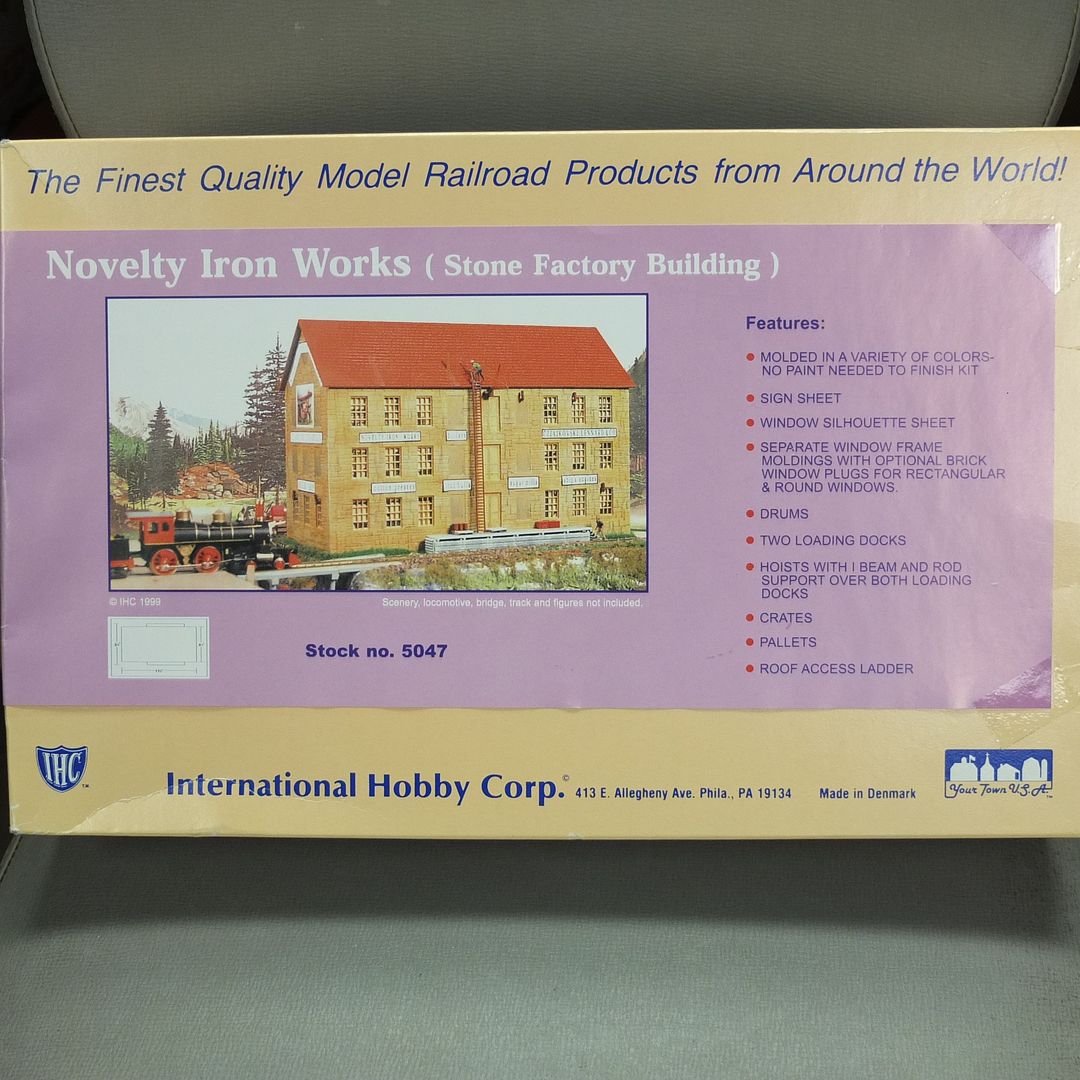

This simple IHC kit was built with both long walls facing the viewer:

To maintain the proper window spacing, the mating ends needed to be shortened. I picked the most advantageous point on each piece, then, after cementing them together and reinforcing the rear surface of the joint with a sheet of .060" sheet styrene, I re-scribed the mortar lines using a #11 X-Acto blade and a dental scraper. The stones were then painted in various shades of stone-like colours, using a brush. Here's a detail view showing the stonework.

As you can see, some of the thinned paint which I used ran into the mortar lines. The lower portion shows why that was not a concern, as I used a rag over my fingertip to apply pre-mixed drywall mud to represent mortar. This covers the stone completely, making the colour differences more subtle. Once the mud has dried (only a few minutes) I used a dry rag to wipe off the excess - best to do this outside, and shake out the rag often, preferably staying upwind of the shaking activity.

Here's the building after the walls have been assembled, painted and had mortar added. The splice is approximately mid-way along the wall, and isn't noticeable even close-up:

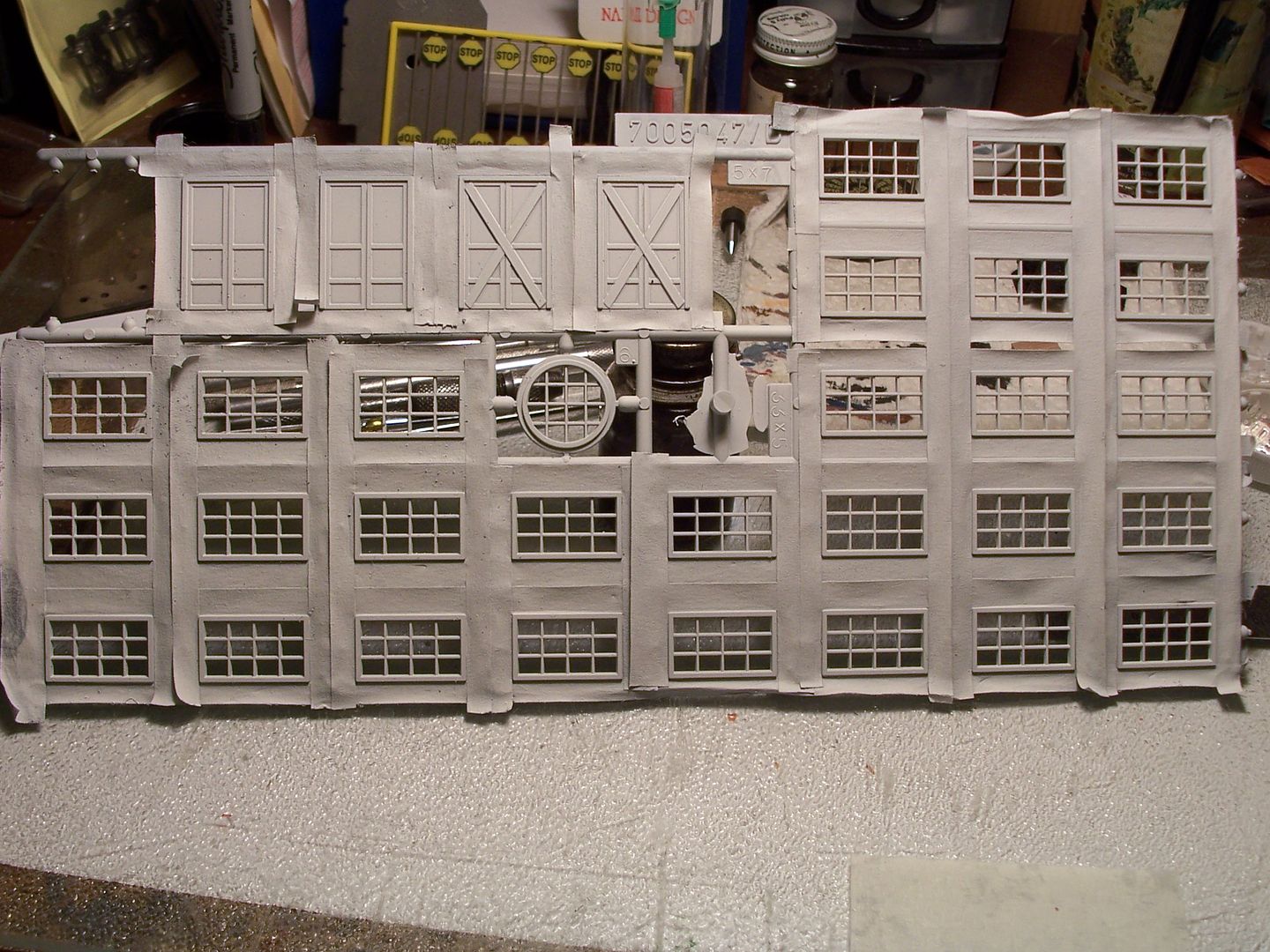

For detail parts, such as doors, windows, and trim, it's often easiest to paint them while they're still on the sprue. Lay out some masking tape, sticky-side down, on a sheet of glass, then use a sharp blade to cut it into strips suitable to mask the gluing surfaces - in the photo below, most strips are continuous, crossing one another where they meet. This shows the sprue after painting with grey primer:

...and here, after an application of white, with the tape removed. The gluing surfaces, dark green, are paint-free and ready to be added to the walls using solvent cement:

For corners with bevelled edges which fit poorly (this structure wasn't bad at all) it often helps to increase the angle of the bevel, so that only the visible edges touch. I use a piece of 150 grit sandpaper, face-up on the workbench, then, while holding the wall, also face-up and at an appropriate angle, draw or push the wall's bevelled edge across the paper - I've found that drawing and pushing increases the chances of damaging the visible portion of the bevel's edge.

Apply solvent-type cement to both edges, let it sit for half a minute-or-so to allow the plastic to soften slightly, then recoat both surfaces and bring them together with some pressure. Don't worry if some plastic oozes out. Place the longer wall face-down on a flat surface, then use a machinist's square to align the joined wall vertically. Next, add a full-height strip of Evergreen square stock - .100" or .125" works well for big structures, while .060" is okay for smaller ones - to the inside of the corner. Carefully push it into place while holding the wall sections from moving so that the corner joint doesn't separate from the pressure and so that the vertical wall remains so, then add solvent cement along both edges of the strip where it touches the walls. Capilliary action will draw it into the joint. Let the joints cure fully (overnight) before moving anything, then use a sharp blade to trim away any material which has oozed out and to re-scribe any filled-in mortar lines, carrying them around the corners. I lightly sanded the exterior of the corners to remove the overly-sharp edges of the stone.

Here's the structure in place, with the surrounding area yat to be finished:

Wayne